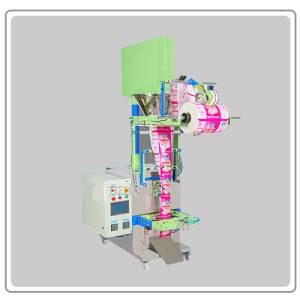

Revolutionize your powder packaging with our cutting-edge automatic powder packing machine! Designed for efficiency and precision, this machine offers a seamless solution for packaging a wide range of powdered products, from food ingredients and pharmaceuticals to chemicals and cosmetics. Boost your productivity and maintain consistent quality with this reliable and versatile equipment.

Contact us today for a quote and to discuss your specific powder packaging needs! [Include contact information]