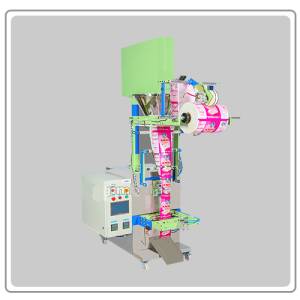

Revolutionize your powder packaging with the X1000, a high-performance, fully automatic machine designed for efficient and precise powder filling. This robust machine is ideal for a wide range of industries, including food, pharmaceuticals, chemicals, and cosmetics. The X1000 offers unparalleled speed, accuracy, and ease of use, maximizing your production output and minimizing waste.

Key Features:

Technical Specifications:

Optional Features:

Benefits:

Contact us today for a quotation and to discuss your specific packaging requirements. We offer customized solutions to meet your unique needs.