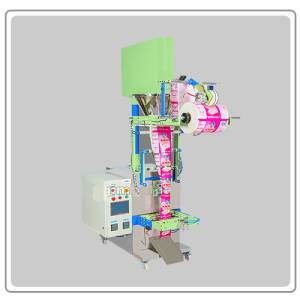

This fully automatic powder packing machine is engineered for high-speed, accurate, and efficient packaging of various powdered materials. Ideal for food, pharmaceutical, chemical, and cosmetic industries, this machine delivers superior performance and minimizes waste, maximizing your production output and profitability.

Key Features:

Technical Specifications:

Benefits:

Contact us today for a quote and to discuss your specific powder packaging needs! We offer comprehensive installation, training, and after-sales support.