Description

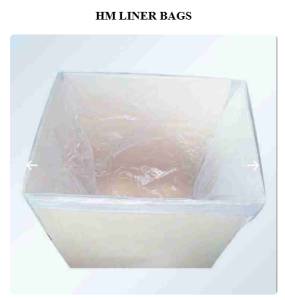

HM LINER BAGS: The Dependable, Cost-Effective Solution for Superior Containment

Safeguard your products, maintain hygiene, and optimize your operations with HM LINER BAGS. Engineered from high-molecular-weight polyethylene (HM-HDPE), these versatile bags offer exceptional strength, robust barrier protection, and a lightweight, economical design, making them ideal for a wide range of industrial, commercial, and food-grade applications.

What are HM LINER BAGS?

HM Liner Bags are specially formulated polyethylene bags designed to line various containers such as boxes, bins, drums, crates, and gaylords. Made from High Molecular Weight - High-Density Polyethylene, they are known for their high tensile strength, excellent moisture barrier, and thin, crinkly texture. This unique material allows for the use of less plastic while still providing superior protection and containment compared to many other film types.

Key Features & Advantages

- Premium HM-HDPE Construction: Utilizes high-molecular-weight polyethylene for a combination of strength and thinness, offering a cost-effective alternative.

- Exceptional Tensile Strength: Despite their lightweight feel, HM Liner Bags boast impressive tear and puncture resistance, ensuring reliable containment even for demanding contents.

- Superior Moisture & Vapor Barrier: Provides excellent protection against moisture, humidity, and odors, preserving the quality and integrity of your products.

- Lightweight & Space-Saving: The thin gauge of HM-HDPE reduces material weight and takes up less storage space, optimizing your logistics and reducing waste.

- Wide Temperature Range Tolerance: Suitable for use in various environments, from refrigeration to ambient industrial settings.

- Food-Safe Options Available: Our HM Liner Bags can be manufactured to be FDA compliant for direct food contact, making them ideal for the food processing and agricultural industries.

- Chemical Resistance: Offers good resistance to many chemicals, fats, and oils, preventing leaks and contamination.

- Variety of Sizes & Gauges: Available in a comprehensive range of dimensions and thicknesses to perfectly fit your specific containers and product requirements.

- Cost-Effective Solution: The inherent strength of HM-HDPE allows for thinner films, translating into significant material cost savings without compromising performance.

- Convenient Dispensing: Typically supplied on perforated rolls or in flat packs for easy, efficient access and dispensing.

Benefits for Your Business

- Superior Product Protection: Guard against dust, dirt, moisture, odors, and cross-contamination, ensuring your goods arrive in pristine condition.

- Enhanced Hygiene & Cleanliness: Keep your primary containers clean, reducing the need for washing and extending their lifespan.

- Operational Efficiency: Easy to insert and remove, streamlining your packaging and handling processes.

- Reduced Material & Shipping Costs: Lighter bags mean lower freight expenses and less raw material usage.

- Versatile Application: Adaptable to numerous industries and product types, from delicate food items to robust industrial components.

- Reliable Performance: Consistent quality and robust construction provide peace of mind in critical applications.

Ideal Applications

- Food Processing & Agriculture:

- Lining bins for meat, poultry, seafood, and dairy products.

- Containment for fruits, vegetables, and bakery ingredients.

- Bulk packaging for grains, flours, spices, and other dry goods.

- Protecting ready-to-eat meals and frozen foods.

- Chemical & Pharmaceutical:

- Lining drums and boxes for powders, granules, and active pharmaceutical ingredients.

- Containing non-hazardous chemicals and resins.

- Manufacturing & Industrial:

- Lining containers for small parts, components, and finished goods.

- Protecting electronic components from static (with anti-static treatments, if specified).

- Containment of waste and refuse in industrial settings.

- Warehousing & Logistics:

- General purpose container liners for storage and shipping.

- Protecting goods during transit from external elements.

- Retail & Institutions:

- High-capacity bin liners for refuse and general waste.

- Laundry bags and storage solutions.

Technical Specifications (Customizable)

- Material: HM-HDPE (High Molecular Weight - High Density Polyethylene)

- Thickness (Gauge): Typically ranging from 8 micron (0.3 mil) up to 50 micron (2 mil), customizable based on application.

- Sizes: Available in flat bags, gusseted bags, and custom dimensions to fit any container.

- Colors: Standard clear, translucent, opaque, or custom colors.

- Roll Type: Continuous rolls, perforated rolls, or individually folded flat packs.

- Certifications: FDA compliant options available for food contact, ISO certified manufacturing processes.

Why Choose Our HM LINER BAGS?

We are committed to providing superior packaging solutions tailored to your unique needs. Our HM Liner Bags are manufactured under stringent quality controls, ensuring consistent performance and reliability. With extensive customization options, competitive pricing, and dedicated customer support, we are your trusted partner for high-quality HM-HDPE liners.

Elevate your containment strategy with the strength, efficiency, and cost-effectiveness of HM LINER BAGS.

Contact us today for a personalized quote or to discuss your specific requirements. Our experts are ready to help you find the perfect liner solution!