Description

Here's a detailed product description for Cable Trays, formatted in Markdown:

High-Performance Cable Tray Systems: Organize, Protect, and Future-Proof Your Infrastructure

Product Overview

Our Cable Tray Systems provide an unparalleled solution for managing, supporting, and protecting power, data, and fiber optic cables across a multitude of industrial, commercial, and institutional environments. Designed for efficiency, durability, and scalability, these systems ensure a neat, organized, and safe cabling infrastructure, reducing installation time, maintenance costs, and potential hazards.

Whether you're setting up a new data center, upgrading an industrial plant, or managing building services, our cable trays offer the flexibility and robust performance required for optimal cable routing and longevity.

Key Features & Benefits

- Superior Cable Organization:

- Benefit: Eliminates tangled cables, reduces clutter, and provides a clear, logical pathway for all wiring. This enhances aesthetics and simplifies identification and troubleshooting.

- Robust Cable Protection:

- Benefit: Shields cables from physical damage, dust, debris, and potential crushing, extending cable lifespan and preventing costly outages.

- Enhanced Safety & Performance:

- Benefit: Reduces tripping hazards and allows for proper ventilation, preventing heat buildup in high-density cable runs, which is crucial for cable performance and longevity.

- Versatile Design & Scalability:

- Benefit: Modular components allow for easy configuration around obstacles, vertical and horizontal changes in direction, and seamless expansion for future cabling needs without major overhauls.

- Durable Construction:

- Benefit: Manufactured from high-quality materials, ensuring exceptional strength, corrosion resistance, and a long service life even in demanding environments.

- Ease of Installation:

- Benefit: Lightweight yet strong designs, combined with a comprehensive range of accessories, facilitate quick and straightforward installation, significantly reducing labor costs and project timelines.

- Improved Accessibility for Maintenance:

- Benefit: Open designs (depending on type) provide easy access for inspection, addition, or removal of cables, streamlining maintenance and future upgrades.

- Compliance with Industry Standards:

- Benefit: Engineered to meet or exceed relevant industry standards (e.g., NEMA, UL, IEC), ensuring reliability, safety, and compatibility with other infrastructure components.

Available Configurations & Materials

We offer a comprehensive range of cable tray types and materials to suit any application:

Available Types:

- Ladder Type: Ideal for heavy power cables, allowing maximum ventilation and easy cable drops.

- Trough Type (Perforated): Offers solid bottom cable support with ventilation through perforations, suitable for sensitive cables and light-duty power cables.

- Wire Mesh Type (Basket Tray): Extremely flexible and easy to cut/bend on-site, perfect for data and communication cables.

- Solid Bottom Type: Provides maximum protection for sensitive cables, shielding them from EMI/RFI and falling debris.

- Channel Type: For single cable runs or small bundles, often used as support for conduit or raceways.

Material Options:

- Pre-Galvanized Steel (GI): Cost-effective, suitable for indoor dry environments, offering basic corrosion resistance.

- Hot-Dip Galvanized (HDG) Steel: Provides superior corrosion protection, ideal for outdoor and industrial applications with moderate exposure to moisture and chemicals.

- Stainless Steel (SS 304 / SS 316): Offers excellent resistance to corrosion, chemicals, and extreme temperatures. Essential for marine, food processing, pharmaceutical, and highly corrosive environments.

- Aluminum: Lightweight, non-magnetic, and inherently corrosion-resistant, often chosen for applications where weight is a concern or in environments where magnetic interference must be minimized.

- Fiber Reinforced Polymer (FRP/GRP): Non-conductive, highly resistant to a broad range of chemicals and UV radiation, making it perfect for chemical plants, wastewater treatment, and other highly corrosive or electrically sensitive areas.

Finish Options:

- Powder Coating: Available in various RAL colors for aesthetic integration and additional protection against corrosion.

- Electro-Zinc Plating: Offers a bright finish and moderate corrosion resistance, typically for indoor applications.

Technical Specifications (General)

- Widths: Available from 50mm (2") up to 1000mm (40")

- Side Rail Heights: Ranging from 25mm (1") to 150mm (6")

- Standard Lengths: 2.4 meters (8 ft), 3.0 meters (10 ft) (Custom lengths available upon request)

- Material Thickness/Gauge: Varies based on material and load capacity requirements (e.g., 1.2mm, 1.5mm, 2.0mm, 2.5mm)

- Load Capacity: Engineered to specific load ratings per NEMA VE 1 or project requirements.

- Compliance: NEMA VE 1, UL, CSA, IEC (where applicable)

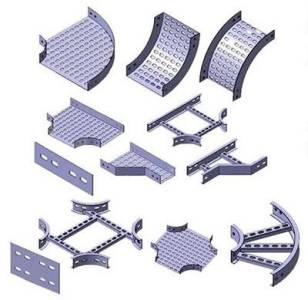

Comprehensive Range of Accessories

To complete your cable management system, we offer a full suite of accessories, ensuring seamless integration and functionality:

- Bends: Horizontal (90°, 60°, 45°, 30°), Vertical Inside & Outside

- Reducers: Left, Right, & Straight

- Tees & Crosses: For branching multiple directions

- Couplers & Connectors: Straight, adjustable, splice plates

- Supports & Hangers: Wall brackets, trapeze hangers, cantilever arms, ceiling rods

- Covers: Solid, vented, louvered for added protection

- Dividers & Barriers: To separate different cable types (e.g., power from data)

- Clamps & Fasteners: For secure installation

Ideal Applications

- Data Centers & Server Rooms: High-density cable management, airflow optimization.

- Industrial Facilities: Manufacturing plants, power generation, oil & gas, mining.

- Commercial Buildings: Offices, hospitals, educational institutions, retail spaces.

- Infrastructure Projects: Tunnels, bridges, railways, airports.

- Public Utilities: Water treatment plants, telecommunications.

- Cleanroom Environments: Pharmaceutical, semiconductor manufacturing (stainless steel, specialized finishes).

Why Choose Our Cable Tray Systems?

- Uncompromising Quality: We use only premium materials and advanced manufacturing processes to ensure products that stand the test of time.

- Expert Design & Support: Our team can assist with system design, material selection, and custom solutions to meet your unique project requirements.

- Competitive Pricing: High-quality solutions without compromising your budget.

- Global Standards: Products designed and manufactured to meet international quality and safety standards.

- Customer-Centric Service: Dedicated support from inquiry to installation and beyond.

Ready to streamline your cable management? Contact us today for a consultation or to request a detailed quote. Let our experts help you design the perfect cable tray system for your project.

[Your Company Name/Website/Contact Info]