Description

Here's a detailed product description for a "Coupling" in Markdown format, focusing on a generic mechanical power transmission shaft coupling as it's the most common and versatile interpretation. I'll include sections that allow for specific customization.

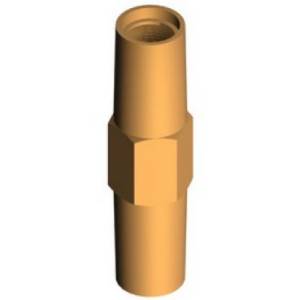

High-Performance Industrial Power Transmission Coupling

The Essential Link for Reliable Motion and Power

In demanding industrial environments, the integrity of your drive system hinges on robust and reliable connections. Our Industrial Power Transmission Couplings are engineered to be the crucial link between driving and driven shafts, ensuring seamless torque transfer, superior vibration damping, and precise accommodation of shaft misalignments. Designed for longevity and peak performance, our couplings protect your valuable machinery, reduce downtime, and enhance operational efficiency across countless applications.

Key Features & Benefits

Unrivaled Reliability & Durability:

- Robust Construction: Manufactured from high-grade materials such as hardened alloy steel, stainless steel, cast iron, or aerospace-grade aluminum, ensuring exceptional strength and wear resistance.

- Precision Machining: Minimizes backlash and ensures balanced operation, critical for high-speed and precision applications.

- Corrosion Resistance: Available with specialized coatings or in material options (e.g., stainless steel) to withstand harsh, corrosive, or washdown environments.

- Extended Service Life: Engineered to reduce stress on connected equipment, prolonging the lifespan of motors, gearboxes, pumps, and bearings.

Optimized Performance & Efficiency:

- Superior Torque Transmission: Reliably transfers power from fractions of a Newton-meter to several thousand, maintaining efficiency even under fluctuating loads.

- Misalignment Compensation: Expertly accommodates various forms of shaft misalignment – angular, parallel, and axial – preventing premature wear and energy loss.

- Vibration Damping: Many designs incorporate elastomeric elements or specific geometries to absorb shock loads and dampen torsional vibrations, leading to smoother operation and reduced noise.

- Temperature Versatility: Designed to perform consistently across wide operating temperature ranges, from cryogenic to high-heat industrial processes.

Ease of Installation & Maintenance:

- Variety of Mounting Options: Available with keyways, set screws, clamp hubs, or taper lock systems for flexible and secure shaft attachment.

- Modular & Split Designs: Facilitate quicker installation and replacement without disturbing connected equipment (depending on coupling type).

- Low to Maintenance-Free: Many designs require minimal to no lubrication, reducing ongoing maintenance costs and associated downtime.

Applications

Our versatile range of couplings serves a vast array of industries and applications, including but not limited to:

- Pumps & Compressors: Ensuring smooth fluid transfer and pressure generation.

- Motors & Generators: Connecting power sources to driven machinery.

- Conveyor Systems: Reliable power transmission for material handling.

- Gearboxes & Reducers: Bridging input and output shafts.

- Machine Tools & Robotics: Precision alignment and zero-backlash options for accurate positioning.

- Textile Machinery: High-speed, low-vibration performance.

- Packaging Equipment: Fast, accurate indexing and continuous motion.

- HVAC Systems: Dampening vibrations in fans and blowers.

- Food & Beverage: Stainless steel options for hygienic environments.

- Oil & Gas: Robust designs for heavy-duty applications.

Technical Specifications (Vary by Model/Type)

To specify the correct coupling for your needs, consider the following parameters:

- Type: Jaw, Grid, Gear, Disc, Elastomeric, Fluid, Bellows, Oldham, Beam, Rigid, etc.

- Materials: Alloy Steel, Stainless Steel (303, 304, 316), Aluminum, Cast Iron, Nylon, Urethane, Nitrile Rubber.

- Torque Capacity: [e.g., 0.1 Nm to 50,000 Nm / 1 lb-in to 442,500 lb-in]

- Maximum Speed: [e.g., Up to 30,000 RPM (depending on size and type)]

- Bore Diameter Range: [e.g., 3 mm to 300 mm / 0.125 inches to 12 inches]

- Operating Temperature: [e.g., -40°C to +150°C / -40°F to +300°F (material dependent)]

- Misalignment Capability:

- Angular: [e.g., Up to 3 degrees]

- Parallel: [e.g., Up to 5 mm / 0.2 inches]

- Axial: [e.g., Up to 10 mm / 0.4 inches]

- Hardness of Elastomer (if applicable): [e.g., 98 Shore A, 92 Shore A, 85 Shore A]

- Standards Compliance: [e.g., ISO, DIN, ANSI, ATEX (for specific models)]

Choosing the Right Coupling

Selecting the ideal coupling requires careful consideration of your application's specific demands. Our engineering team is ready to assist you in evaluating factors such as:

- Peak and Continuous Torque Requirements

- Maximum Operating Speed

- Shaft Diameters and Keyway/Spline Specifications

- Type and Degree of Misalignment

- Environmental Conditions (temperature, moisture, corrosives, dust)

- Space Constraints and Mounting Orientation

- Desired Service Life and Maintenance Schedule

- Shock Load and Vibration Characteristics

Why Choose Our Couplings?

We are committed to delivering excellence through:

- Superior Quality: Rigorous manufacturing processes and quality control ensure every coupling meets the highest standards.

- Extensive Range: A comprehensive portfolio to match virtually any industrial application.

- Technical Expertise: Our experienced team provides unparalleled support from selection to installation.

- Customization Options: Solutions tailored to unique application requirements.

- Global Availability: Reliable supply chain to meet your demands worldwide.

Protect Your Investment. Enhance Your Performance.

Contact us today to discuss your specific coupling requirements or to request a detailed quote. Let our expertise optimize your power transmission solutions!