Description

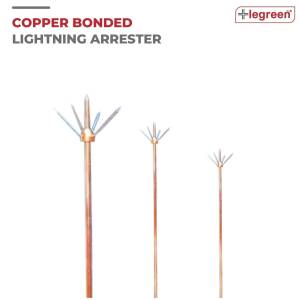

COPPER BONDED LIGHTING ARRESTER

Unwavering Protection Against Nature's Fury

Safeguard your valuable assets, structures, and personnel from the destructive power of lightning with our premium Copper Bonded Lighting Arresters. Engineered for superior performance, exceptional durability, and cost-effectiveness, this essential component forms the cornerstone of any reliable lightning protection system.

Product Overview

Our Copper Bonded Lighting Arrester (also known as a Copper Bonded Earth Rod or Grounding Rod when referring to its primary function in a grounding system) is specifically designed to provide a low-impedance path for lightning current to safely dissipate into the earth. It features a high-tensile steel core for unparalleled strength, permanently molecularly bonded with a thick layer of pure electrolytic copper. This innovative construction combines the best properties of both materials, offering a robust, corrosion-resistant, and highly conductive solution.

Key Features

- Superior Conductivity: A uniform, thick layer of 99.9% pure electrolytic copper ensures excellent electrical conductivity, effectively channeling high lightning currents to the ground.

- High Tensile Strength Steel Core: The robust steel core provides exceptional mechanical strength, allowing for deep ground penetration without bending or breaking, and resisting structural damage over time.

- Molecular Bonding: Unlike electroplating, our copper bonding process creates a permanent, non-peeling molecular bond between copper and steel. This ensures a consistent, low-resistance connection that will not degrade or delaminate.

- Exceptional Corrosion Resistance: The copper layer offers superior resistance to corrosion, rust, and oxidation in diverse soil conditions, ensuring a long and reliable service life.

- Long Service Life: Designed to withstand harsh environmental conditions, including moisture, extreme temperatures, and chemical exposure in the soil, for decades of maintenance-free operation.

- Cost-Effective Solution: Offers comparable performance to solid copper rods at a significantly lower cost, providing an economical yet highly effective grounding solution.

- Consistent Thickness: The copper layer is applied with precise, uniform thickness across the entire rod, guaranteeing consistent performance and protection.

- Theft Deterrent: Less attractive to thieves than solid copper, reducing replacement costs and downtime.

Benefits

- Unmatched Safety: Provides a safe discharge path for lightning strikes, minimizing the risk of fire, structural damage, electrical faults, and injury to personnel.

- Asset Protection: Protects sensitive electronic equipment, machinery, data centers, and critical infrastructure from costly surge damage.

- Enhanced Reliability: Ensures the continuous operation of electrical systems and equipment by maintaining a stable and effective grounding system.

- Compliance with Standards: Helps meet national and international electrical codes and safety standards for lightning protection and grounding.

- Reduced Maintenance: Its inherent durability and corrosion resistance significantly reduce the need for inspection, repair, or replacement.

- Versatile Application: Suitable for a wide range of installations, from residential and commercial buildings to complex industrial and utility environments.

Technical Specifications (Typical)

- Material: High-Tensile Steel Core (ASTM A53 / IS 2062 equivalent) with a Molecularly Bonded Electrolytic Copper Layer (99.9% purity).

- Copper Layer Thickness:

- Standard: 250 microns (µm) / 0.25mm

- Heavy Duty: 350 microns (µm) / 0.35mm (or as per customer specification)

- Tensile Strength: >400 N/mm² (for the steel core)

- Conductivity: >25% IACS (International Annealed Copper Standard)

- Rod Diameter: 14.2mm, 17.2mm, 20mm (common sizes), or customized

- Rod Length: 1 meter (3.3 ft), 2 meters (6.6 ft), 3 meters (9.8 ft) (or customized)

- Connection Type: Threaded (for coupling with extension rods) or Pointed (for initial ground insertion).

- Operating Temperature: -40°C to +80°C

- Standards Complied: UL 467, IEEE 80, IEC 62305, BS 7430 (or equivalent regional standards)

Applications

Our Copper Bonded Lighting Arresters are an indispensable component for grounding and lightning protection systems in:

- Residential & Commercial Buildings: Homes, offices, shopping centers, hotels.

- Industrial Facilities: Factories, warehouses, manufacturing plants.

- Data Centers & Telecom Towers: Protecting critical IT infrastructure and communication networks.

- Power Generation & Distribution: Substations, power plants (conventional & renewable), transmission lines.

- Renewable Energy Sites: Solar farms, wind turbine installations.

- Oil & Gas Installations: Refineries, drilling platforms, pipelines.

- Healthcare Facilities: Hospitals, clinics.

- Transportation Infrastructure: Airports, railway systems.

Why Choose Our Copper Bonded Lighting Arrester?

When it comes to lightning protection, compromise is not an option. Our Copper Bonded Lighting Arresters deliver:

- Guaranteed Performance: Engineered to exact specifications for maximum conductivity and robust mechanical strength.

- Unrivaled Durability: A molecular bond and superior corrosion resistance ensure long-term, reliable protection.

- Economical Efficiency: Get the benefits of copper at a fraction of the cost of solid copper solutions.

- Industry Compliance: Manufactured to meet stringent international and national safety standards.

- Expert Support: Backed by our commitment to quality and customer satisfaction.

Ordering Information

Our Copper Bonded Lighting Arresters are available in a range of standard diameters and lengths, with options for various copper layer thicknesses to meet specific project requirements. Custom sizes and specifications can also be accommodated.

Contact our sales team today to discuss your lightning protection needs and receive a comprehensive quote. Ensure the safety and longevity of your investments with our superior Copper Bonded Lighting Arresters.

Note: For optimal performance and safety, all lightning protection and grounding systems should be designed and installed by qualified professionals in accordance with local and international electrical codes and standards.