Ensure unparalleled electrical safety and system reliability with our premium Copper Bonded Grounding Electrodes. Engineered for superior conductivity and exceptional corrosion resistance, these electrodes provide a robust and long-lasting earthing solution for a wide range of electrical, lightning protection, and telecommunication applications. By molecularly bonding a uniform layer of high-purity copper onto a high-tensile steel core, we deliver an electrode that offers the best of both worlds: the strength of steel and the supreme electrical properties and longevity of copper.

Our Copper Bonded Grounding Electrodes are indispensable for providing safe and effective earthing across various sectors:

Our Copper Bonded Electrodes are designed for straightforward installation. They can be easily driven into the earth using a power hammer or manual methods. Ensure proper connection to the grounding conductor using approved copper or brass grounding clamps. Once installed, these electrodes are generally maintenance-free; however, periodic inspection of connections is recommended to ensure long-term effectiveness.

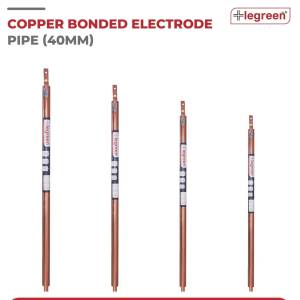

We offer a comprehensive range of Copper Bonded Grounding Electrodes to suit diverse project requirements. Please specify:

Accessories: We also supply a full range of compatible accessories, including: