Description

Robust & Versatile Mild Steel (MS) Pipe Fittings

Description:

Discover our premium range of Mild Steel (MS) Pipe Fittings, engineered for superior strength, durability, and cost-effectiveness across a multitude of industrial, commercial, and structural applications. Our MS fittings are meticulously manufactured to meet stringent industry standards, ensuring reliable performance and seamless integration into your piping systems.

Mild Steel fittings are renowned for their excellent weldability, high tensile strength, and remarkable resistance to shock and vibration, making them an ideal choice for transporting water, gas, oil, steam, and other non-corrosive fluids and gases under various pressure and temperature conditions.

Key Features & Benefits:

- High Tensile Strength: Manufactured from high-grade mild steel, our fittings offer exceptional mechanical strength, allowing them to withstand high pressures and mechanical stresses without deformation or failure.

- Superior Durability: Built to last, these fittings provide a long service life, reducing the need for frequent replacements and minimizing maintenance costs.

- Cost-Effective Solution: Mild steel is an economical material, making our MS fittings a budget-friendly choice without compromising on quality or performance.

- Excellent Weldability: Designed for ease of fabrication, our fittings can be readily welded, ensuring strong, leak-proof joints and simplifying installation processes.

- Versatile Applications: Suitable for a wide array of environments and media, from general plumbing to heavy industrial use.

- Dimensional Accuracy: Precision-engineered to exact specifications, guaranteeing a perfect fit and efficient system performance.

- Customization Options: Available in various sizes, wall thicknesses, and connection types to perfectly match your project requirements.

- Corrosion Protection Ready: While mild steel is susceptible to rust, our fittings are perfect for priming, painting, galvanizing, or coating to enhance corrosion resistance in specific environments.

Common Applications:

- Industrial Piping Systems: Chemical plants, refineries, power generation, manufacturing facilities.

- Water & Wastewater Treatment: Municipal water supply lines, sewage systems.

- Oil & Gas Industry: Low-pressure pipelines, non-corrosive fluid transfer.

- HVAC Systems: Heating, ventilation, and air conditioning ductwork and piping.

- Fire Fighting Systems: Sprinkler and standpipe systems.

- Structural Frameworks: Handrails, supports, and general fabrication.

- Plumbing & General Construction: Commercial and residential building projects.

- Agricultural Irrigation Systems: Water distribution networks.

- Compressed Air Lines: Industrial air supply systems.

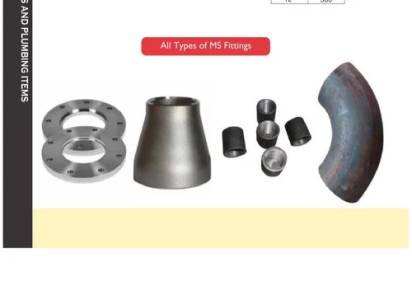

Available Types:

We offer a comprehensive range of MS fittings to complete any piping network:

- Elbows: 90 Degree Elbows, 45 Degree Elbows (Long Radius & Short Radius)

- Tees: Equal Tee, Reducing Tee

- Reducers: Concentric Reducer, Eccentric Reducer

- Caps: Pipe Caps

- Couplings: Full Coupling, Half Coupling, Reducing Coupling

- Unions: Threaded Unions

- Nipples: Barrel Nipple, Welding Nipple, Close Nipple

- Flanges: Slip-On Flanges, Weld Neck Flanges, Blind Flanges, Threaded Flanges

- Crosses: Equal Cross, Reducing Cross

- Plugs: Hex Head Plugs, Round Head Plugs

Technical Specifications (Illustrative - Specifics Vary by Product):

- Material: High-grade Mild Steel (e.g., ASTM A234 WPB, IS 1239, EN 10253)

- Size Range: NPS 1/2" to 48" (DN15 to DN1200)

- Wall Thickness: SCH 10, SCH 20, SCH 30, STD, SCH 40, SCH 60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS (and custom thicknesses)

- Connection Type:

- Butt-Weld: For seamless, high-integrity connections.

- Socket-Weld: For smaller pipe diameters, providing a strong, leak-proof joint.

- Threaded: NPT, BSPT, BSPP (for easy assembly and disassembly).

- Manufacturing Standards:

- ASME B16.9 (Butt-weld Fittings)

- ASME B16.11 (Forged Fittings, Socket-welding and Threaded)

- ASME B16.5 (Pipe Flanges and Flanged Fittings)

- DIN Standards, EN Standards, IS Standards, JIS Standards

- Surface Finish: Black (Mill Finish), Varnished, Primed (Red Oxide, Black), Galvanized (on request)

Why Choose Our MS Fittings?

- Quality Assurance: Each fitting undergoes rigorous quality checks to ensure compliance with international standards and superior performance.

- Extensive Inventory: A broad selection of sizes and types readily available to meet urgent project timelines.

- Competitive Pricing: Get the best value for your investment without compromising on product integrity.

- Expert Support: Our knowledgeable team is ready to assist you in selecting the right fittings for your specific application.

- Reliable Supply Chain: Efficient logistics ensure timely delivery to your doorstep.

Elevate the integrity and performance of your piping systems with our robust and reliable Mild Steel (MS) Pipe Fittings.

Contact us today for a quote or to discuss your specific requirements!