Description

Here's a detailed product description for an FLP Panel, formatted in Markdown:

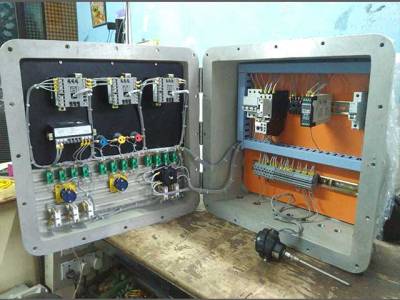

FLP Panel (Flameproof / Explosion-Proof Control & Distribution System)

Engineered for Uncompromising Safety in Hazardous Environments

In hazardous industrial environments where the presence of flammable gases, vapors, dusts, or fibers poses a significant risk, safety is paramount. Our FLP (Flameproof / Explosion-Proof) Panels are meticulously engineered to provide uncompromising electrical control and distribution solutions, ensuring operational safety and regulatory compliance in the most demanding conditions.

Designed to prevent the ignition of explosive atmospheres, our FLP Panels are robust, reliable, and customizable, offering peace of mind where safety cannot be compromised.

Key Features:

- Robust Flameproof Enclosure: Constructed from heavy-duty, corrosion-resistant materials such as cast aluminum alloy (LM6) or marine-grade stainless steel (304/316L). Designed and tested to withstand internal explosions and prevent flame propagation to the external atmosphere.

- Certified Internal Components: Houses a comprehensive range of pre-wired and certified electrical components including MCBs, MCCBs, contactors, relays, timers, power supplies, terminal blocks, indicating lamps, push buttons, selector switches, and meters – all individually rated for hazardous area applications.

- Precision Machined Joints: Engineered with exact tolerance, flame-quenching gaps (flame paths) at all joints (doors, covers, conduit entries) to cool hot gases below their ignition temperature before they can exit the enclosure.

- High-Integrity Sealing: Equipped with durable, weather-resistant gaskets (e.g., neoprene, silicone, EPDM) to ensure an Ingress Protection (IP) rating of IP55, IP65, or IP66, safeguarding against dust, water jets, and corrosive agents.

- Certified Cable Entries: Supplied with a variety of certified flameproof cable glands (Ex 'd') suitable for armored, unarmored, and specialized cables, ensuring secure, sealed, and safe cable termination points (NPT, Metric threads available).

- External Controls & Indicators: Option for externally operable flameproof push buttons, selector switches, emergency stops, and LED indicators for safe control and monitoring without opening the enclosure.

- Viewing Window (Optional): Toughened borosilicate glass window available for safe visual inspection of internal components, meters, and readouts without compromising the flameproof integrity.

- Modular & Customizable Design: Available in various sizes and configurations (e.g., motor starter, distribution board, control station, junction box) to suit specific control, distribution, or monitoring requirements. Fully customizable based on customer schematic diagrams and specifications.

- Corrosion & Weather Resistance: Designed for long-term reliability and minimal maintenance in harsh industrial environments, including high humidity, extreme temperatures, and chemical exposure.

- Easy Access & Maintenance: Hinged door with robust locking mechanisms and specialized fasteners for secure yet accessible maintenance (when de-energized and safe to open).

- Mounting Options: Suitable for wall mounting, skid mounting, or floor standing configurations.

Benefits You Can Rely On:

- Uncompromised Safety: Eliminates the risk of igniting explosive atmospheres, protecting personnel, critical assets, and the environment.

- Regulatory Compliance: Ensures strict adherence to international and national hazardous area classifications and standards (e.g., ATEX, IECEx, IS/IEC), simplifying certification processes.

- Maximum Uptime: Robust construction, high-quality components, and superior engineering minimize downtime and reduce maintenance requirements.

- Tailored Solutions: Custom configurations mean you get a panel precisely designed for your specific process needs, optimizing performance and integration.

- Durability in Harsh Conditions: Built to withstand corrosive chemicals, extreme temperatures, mechanical stress, and vibration, extending product lifespan and reducing replacement costs.

- Peace of Mind: Operate with confidence knowing your critical electrical systems are housed in the safest possible enclosure, backed by expert design and rigorous testing.

Ideal Applications:

Our FLP Panels are indispensable in a wide range of industries and hazardous locations, including:

- Oil & Gas: Refineries, Drilling Rigs, Offshore Platforms, Storage Depots, Petrochemical Plants

- Chemical Processing: Manufacturing Plants, Storage Facilities

- Pharmaceutical Manufacturing: Solvent handling areas, processing zones

- Paint & Coating Manufacturing: Production lines, mixing areas

- Power Generation: Coal handling plants, dusty environments

- Food & Beverage: Grain handling and storage, sugar processing, distilleries (dusty/flammable vapor areas)

- Mining Operations: Underground and surface mining (gas & dust)

- Waste Water Treatment Plants: Digester gas areas

- Any Zone 1 or Zone 2 (Gas Group IIA, IIB, IIC) / Zone 21 or Zone 22 (Dust) hazardous area requiring electrical control or distribution.

Technical Specifications (Typical, Customizable):

- Hazardous Area Certification: ATEX, IECEx, IS/IEC, PESO, EAC (Ex 'd')

- Protection Type: Ex "d" (Flameproof)

- Gas Group: IIA, IIB, IIC

- Dust Group: IIIA, IIIB, IIIC

- Zone Rating: Zone 1, Zone 2 (Gas) / Zone 21, Zone 22 (Dust)

- Enclosure Material: Cast Aluminum Alloy (LM6), Stainless Steel (SS304, SS316L)

- Ingress Protection (IP Rating): IP55, IP65, IP66 (as per requirement)

- Voltage Rating: Up to 1100V AC/DC

- Current Rating: As per internal components and application (e.g., up to 630A MCCB)

- Temperature Class: T6, T5, T4, T3 (as per application requirements)

- Ambient Temperature: -20°C to +55°C (standard, wider ranges available)

- Cable Entries: Multiple options for Ex 'd' cable glands (M20, M25, M32, M40, NPT ½", ¾", 1", 1¼", 1½", 2", etc.)

- Internal Components: Circuit breakers (MCB, MCCB, ACB), Contactors, Relays, Timers, Ammeters, Voltmeters, Push Buttons, Selector Switches, Terminal Blocks, Transformers, Power Supplies, etc.

- Mounting: Wall mounting, Floor standing, Skid mounted

- Finish: Powder coated (for aluminum), Natural finish (for SS), or specialized coatings.

- Customization: Fully customizable dimensions, component layouts, and functionalities.

Why Choose Our FLP Panels?

- Expertise & Experience: Decades of experience in designing, manufacturing, and deploying hazardous area electrical solutions.

- Quality Assurance: Rigorous testing, inspections, and quality control at every stage of manufacturing, adhering to international standards.

- Custom Engineering: Our dedicated engineering team works closely with you to design a solution that perfectly fits your operational requirements, safety protocols, and budget.

- Comprehensive Support: From initial consultation and design to installation guidance and after-sales service, we are committed to your long-term satisfaction.

- Global Compliance: Products designed and certified to meet the highest global safety standards, ensuring acceptance in diverse regulatory environments.

Request a Quote Today!

Don't compromise on safety. Invest in a solution that protects your people, your assets, and your operations. Contact our expert team today to discuss your specific FLP Panel requirements and receive a customized quote.

[Your Company Name] [Your Website] | [Your Email] | [Your Phone Number]