Description

Precision Industrial Process Control System: Master Your Operations with Unrivaled Efficiency and Reliability

In today's dynamic industrial landscape, achieving peak operational performance, stringent quality standards, and uncompromised safety is paramount. Our cutting-edge Industrial Process Control System is engineered to be the intelligent backbone of your facility, transforming raw data into actionable insights and automating complex processes with unparalleled precision.

Designed for the most demanding environments, our system empowers you to exert complete command over every variable, ensuring continuous optimization, reduced downtime, and significant cost savings across your entire operational footprint.

Key Features

Our Industrial Process Control System integrates state-of-the-art hardware and software components to deliver a comprehensive solution:

- Modular & Scalable Architecture:

- Flexible design allows for easy expansion and adaptation to evolving operational needs, from single-unit control to enterprise-wide integration.

- Supports a hybrid approach, seamlessly integrating existing PLCs, DCS, and RTUs with our advanced control modules.

- Advanced Control Algorithms:

- Implements sophisticated PID, fuzzy logic, model predictive control (MPC), and adaptive control algorithms for superior process optimization and stability.

- Minimizes process variability, reduces energy consumption, and improves product consistency.

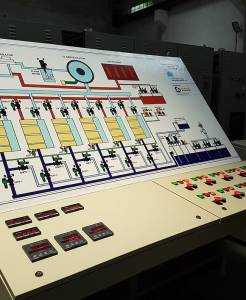

- Intuitive SCADA & HMI:

- User-friendly graphical interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems provide real-time visualization of all process parameters.

- Customizable dashboards, alarm annunciators, and historical trend charts for clear operational oversight.

- Robust Data Acquisition & Logging:

- High-speed, accurate acquisition of data from thousands of sensors and field devices.

- Secure, long-term data logging for historical analysis, compliance reporting, and continuous improvement initiatives.

- Seamless Connectivity & IIoT Integration:

- Supports a wide array of industrial communication protocols (OPC UA, Modbus TCP/RTU, Profinet, EtherNet/IP, DNP3, etc.).

- Leverages Industrial Internet of Things (IIoT) capabilities for cloud connectivity, remote monitoring, and advanced analytics.

- Comprehensive Alarm & Event Management:

- Configurable multi-level alarm system with prioritization, acknowledgment, and historical logging.

- Ensures timely notification of critical events to prevent incidents and minimize operational disruptions.

- Integrated Batch Control Capabilities:

- Fully compliant with ISA-88 standards for recipe management, phase control, and batch reporting, ideal for batch-oriented processes.

- Cybersecurity Features:

- Multi-layered security protocols, including user authentication, role-based access control, data encryption, and network segmentation, to protect against cyber threats.

- Remote Monitoring & Control:

- Secure web and mobile access enables operators and managers to monitor processes and make informed decisions from anywhere, anytime.

Benefits

Implementing our Industrial Process Control System delivers tangible advantages across your organization:

- Boost Operational Efficiency: Minimize waste, optimize resource utilization (energy, raw materials), and streamline workflows for maximum productivity.

- Ensure Product Consistency & Quality: Maintain tight control over process variables to reduce product variations and meet stringent quality specifications consistently.

- Enhance Safety & Compliance: Proactive anomaly detection, comprehensive alarm management, and robust safety interlocks protect personnel, assets, and the environment. Facilitates compliance with industry regulations through detailed data logging and reporting.

- Reduce Downtime & Maintenance Costs: Predictive maintenance capabilities identify potential equipment failures before they occur, reducing unscheduled downtime and optimizing maintenance schedules.

- Maximize Throughput & Yield: Fine-tune process parameters to achieve optimal production rates and improve overall output without compromising quality.

- Gain Real-time Visibility & Control: Empower your team with immediate access to critical operational data, enabling swift, informed decision-making and rapid response to changing conditions.

- Future-Proof Your Operations: A flexible and scalable architecture ensures your investment grows with your business, easily accommodating new technologies and expanding production needs.

Ideal Applications

Our Industrial Process Control System is ideally suited for a diverse range of industries requiring precise and reliable process automation, including:

- Chemical & Petrochemical: Reaction control, distillation, blending, safety interlocks.

- Oil & Gas: Pipeline monitoring, wellhead control, refining processes.

- Food & Beverage: Recipe management, fermentation, pasteurization, packaging.

- Pharmaceutical & Biotech: Batch processing, cleanroom environmental control, validation support.

- Water & Wastewater Treatment: Pumping stations, filtration, chemical dosing, SCADA for entire networks.

- Power Generation: Boiler control, turbine monitoring, grid stability.

- Mining & Metals: Mineral processing, furnace control, material handling.

- Automotive & Discrete Manufacturing: Assembly line automation, robotic integration, quality control.

Technical Specifications (Highlights)

- Supported Control Platforms: Fully compatible with major DCS (Distributed Control Systems), PLC (Programmable Logic Controller), and RTU (Remote Terminal Unit) vendors.

- Communication Protocols: Extensive support for standard industrial protocols (e.g., Modbus TCP/RTU, OPC UA/DA, Profinet, EtherNet/IP, DNP3, IEC 61850) and proprietary protocols via custom drivers.

- Software Integration: Open APIs for seamless integration with ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), LIMS (Laboratory Information Management Systems), and Historian databases.

- Hardware Compatibility: Designed to interface with a wide range of sensors, actuators, and analytical instruments from various manufacturers.

- Reporting & Analytics: Customizable reporting engine for operational, quality, regulatory, and energy consumption reports. Integrated advanced analytics and predictive modeling capabilities.

- Security Standards: Adherence to ISA/IEC 62443 industrial cybersecurity standards.

- Operating Environment: Robust design for harsh industrial environments, including wide temperature ranges and resistance to dust, moisture, and vibration.

Why Choose Our System?

Invest in a future where your industrial processes are not just managed, but mastered. Our commitment to innovation, robust engineering, and unparalleled customer support makes us the partner of choice for optimizing your critical operations. We provide end-to-end solutions, from system design and implementation to ongoing maintenance and training, ensuring your success every step of the way.

Ready to Transform Your Operations?

Contact us today for a personalized consultation or to schedule a live demonstration. Discover how our Industrial Process Control System can elevate your productivity, safety, and profitability.