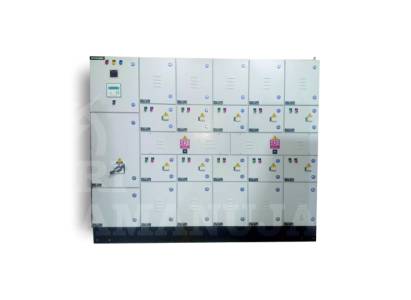

The Capacitor Panel (APFC - Automatic Power Factor Correction) is an indispensable solution designed to intelligently monitor and improve the power factor of electrical loads in industrial, commercial, and utility applications. By automatically switching capacitor banks in and out of the circuit, our APFC panel ensures optimal reactive power compensation, mitigating the penalties associated with low power factor and significantly enhancing the overall efficiency and stability of your electrical system.

| Parameter | Specification |

|---|---|

| Power Rating | 25 kVAr to 1200 kVAr (standard, higher ratings custom-built) |

| Voltage Range | 415V, 440V, 480V, 690V (other voltages available on request) |

| Frequency | 50 Hz / 60 Hz |

| Power Factor Achieved | > 0.99 lagging (at rated load) |

| Control Stages | 4, 6, 8, 12, 14, 16 steps (configurable based on requirement) |

| Capacitor Type | Heavy Duty MPP (Metalized Polypropylene) / APP (All-Polypropylene), Self-Healing, Dry/Gas Filled |

| Insulation Level | 3 kV for 1 minute |

| Harmonic Withstand | Tuned/Detuned filter reactors available for installations with significant harmonic distortion (optional) |

| Controller Type | Microprocessor-based, Multi-stage, Automatic PF Controller |

| Display | LCD/LED for comprehensive parameter display |

| Enclosure Type | Floor-standing, CRCA Sheet Steel, Powder Coated |

| IP Protection | IP41, IP52, IP54 (as per customer requirement) |

| Cooling | Natural Air Ventilation / Forced Air Cooling (for higher ratings) |

| Cable Entry | Top/Bottom (configurable) |

| Standards | IEC 61921, IEC 60831, IS 13340 (or equivalent relevant national/international standards) |

Our APFC Capacitor Panels are ideal for any facility with significant inductive loads that contribute to a low power factor, including:

Don't let inefficient power factor erode your profits and jeopardize your electrical system's performance. Invest in our advanced APFC Capacitor Panel and experience the benefits of optimized power, reduced costs, and enhanced operational efficiency.

Contact us now to discuss your specific requirements and get a personalized quote for an APFC solution that will transform your energy management.