Description

Here's a detailed product description for a Heat Transfer Agitated Vessel, formatted in Markdown:

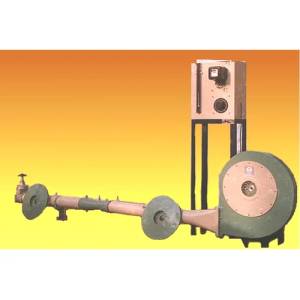

Heat Transfer Agitated Vessel: Precision Temperature Control for Optimal Processing

Unlock unparalleled process efficiency and product consistency with our advanced Heat Transfer Agitated Vessels. Engineered for industries demanding precise temperature control and thorough mixing, these vessels are the cornerstone for critical chemical reactions, dissolution, crystallization, homogenization, and pasteurization processes.

Our Heat Transfer Agitated Vessels are designed to facilitate efficient heat exchange (heating or cooling) while simultaneously ensuring uniform blending or reaction within the vessel's contents. This combination optimizes batch times, enhances product quality, and provides superior control over your most sensitive operations.

Key Features & Engineering Excellence

Our vessels are meticulously designed and fabricated to meet the highest industry standards, ensuring durability, performance, and safety.

- Robust Vessel Construction:

- Materials of Construction: Available in a wide range of materials including 304/304L Stainless Steel, 316/316L Stainless Steel, Hastelloy® Alloys, Duplex Stainless Steel, and specialty alloys for corrosion resistance and process compatibility.

- Internal Finish: Customizable internal finishes from mechanical polish (e.g., Ra < 32 µin / 0.8 µm) to electropolished surfaces for hygienic applications, reduced product adhesion, and easy cleaning.

- Capacity: Ranging from laboratory/pilot scale (e.g., 50 liters) to large industrial volumes (e.g., 50,000 liters or more).

- Pressure & Temperature Ratings: Designed for specific operating pressures (full vacuum to high pressure) and temperatures, with comprehensive calculations and certifications.

- Configuration: Vertical or horizontal orientation, with various bottom configurations (dished, conical, flat sloped) for optimal drainage.

- Advanced Heat Transfer System:

- Jacket Types:

- Full Jacket: Surrounds the entire cylindrical section for maximum heat transfer area.

- Half-Pipe Coil Jacket: Offers excellent heat transfer rates and can handle high-pressure heating/cooling media.

- Dimple Jacket: Provides efficient heat transfer with lower jacket volume and superior strength.

- Internal Coils: Helical or U-tube coils for direct heat exchange within the product (optional).

- Insulation & Cladding: High-efficiency insulation (e.g., mineral wool, cellular glass, polyurethane foam) with external cladding (e.g., polished stainless steel, aluminum) to minimize heat loss/gain and ensure personnel safety.

- Heating/Cooling Media: Compatible with various media such as steam, hot oil, chilled water, glycol, thermal fluids, etc.

- Optimized Agitation System:

- Agitator Drive: Top-entry, bottom-entry, or side-entry options with robust gearmotors (electric or pneumatic) for consistent torque and speed control.

- Impeller Types: A wide selection of impellers tailored to specific process requirements:

- Propeller: For low-viscosity mixing and suspension.

- Turbine (Rushton, Pitched Blade): Versatile for medium-viscosity mixing, dispersion, gas-liquid contacting.

- Anchor/Scraped Surface: Ideal for high-viscosity products, preventing buildup on vessel walls, and improving heat transfer.

- Helical Ribbon: Excellent for very high-viscosity applications.

- Hydrofoil/High-Efficiency Impellers: For gentle mixing and reduced energy consumption.

- Shaft Sealing: Mechanical seals (single or double, with barrier fluid systems), lip seals, or packing glands, selected based on product characteristics and process demands.

- Baffles: Strategically positioned baffles to enhance mixing efficiency, prevent vortexing, and promote uniform flow patterns.

- Integrated Control & Monitoring:

- Temperature Sensors: RTDs or thermocouples for precise product and jacket temperature monitoring.

- Pressure Sensors: For vessel internal pressure and jacket pressure.

- Level Sensors: Continuous or discrete level sensing.

- Variable Frequency Drive (VFD): For agitator speed control, allowing process optimization and energy savings.

- Control Panel: Local or integrated with plant-wide SCADA/PLC systems for automated operation, data logging, and alarm management.

- Sanitary Design & Cleanability (for Hygienic Applications):

- CIP (Clean-in-Place) & SIP (Sterilize-in-Place): Integration of spray balls and optimized vessel geometry for effective automated cleaning and sterilization.

- Crevice-Free Construction: Minimized dead legs and smooth internal welds to prevent bacterial growth and product hang-up.

- FDA, cGMP, and ASME BPE Compliance: Available for pharmaceutical, biotech, and food & beverage industries.

- Auxiliary Connections & Features:

- Inlet/Outlet Nozzles: Configurable for product, heating/cooling media, CIP, and sampling.

- Manway/Access Ports: For easy inspection, cleaning, and maintenance.

- Sight Glass & Illumination: For visual monitoring of the process.

- Sampling Ports: For in-process quality control.

- Vacuum & Pressure Relief Valves: Essential safety devices.

Unmatched Benefits for Your Process

- Precise Temperature Control: Achieve and maintain exact temperatures, crucial for sensitive reactions and product quality.

- Enhanced Mixing Efficiency: Uniform blending eliminates hot/cold spots and ensures consistent product characteristics.

- Optimized Batch Times: Rapid heat transfer and effective mixing reduce processing cycles.

- Improved Product Yield & Quality: Minimized degradation, improved solubility, and consistent results.

- Energy Efficiency: Optimized jacket design and insulation reduce energy consumption.

- Operational Safety: Designed with comprehensive safety features and compliance to international standards.

- Scalability: From R&D to full-scale production, our vessels support seamless process scaling.

- Versatility: Adaptable to a wide range of liquids, slurries, and viscosities.

Ideal for a Diverse Range of Industries

Our Heat Transfer Agitated Vessels are indispensable for numerous applications across various sectors:

- Chemical Processing: Synthesis, polymerization, dissolution, crystallization.

- Pharmaceuticals & Biotechnology: Media preparation, buffer solutions, fermentation, active pharmaceutical ingredient (API) production.

- Food & Beverage: Pasteurization, cooking, blending, syrup preparation, yogurt, sauces.

- Cosmetics & Personal Care: Lotion, cream, shampoo, and emulsion manufacturing.

- Paints, Coatings & Adhesives: Resin production, pigment dispersion, formulation.

- Specialty Chemicals: Grease, lubricant, and catalyst preparation.

- Waste Treatment: Slurry conditioning and chemical reactions.

Tailored to Your Exact Specifications

We understand that every process is unique. Our engineering team works closely with you to design and fabricate a Heat Transfer Agitated Vessel that perfectly matches your operational requirements, facility constraints, and regulatory demands. From specific impeller designs to automation integration, we deliver bespoke solutions.

Elevate Your Process – Contact Us Today!

Ready to optimize your heating, cooling, and mixing operations? Our experts are here to provide detailed technical specifications, discuss your application, and offer a customized solution.

Contact us for a consultation or to request a quote.