Description

Here's a detailed product description for PUF Panels, formatted in Markdown:

Puf Panels: High-Performance Insulated Panels for Modern Construction

Overview: The Core of Energy-Efficient Buildings

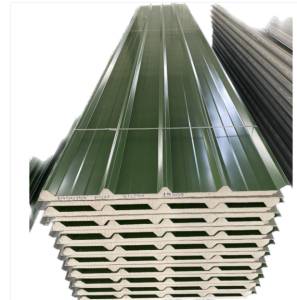

Puf Panels (Polyurethane Foam Panels) are advanced, lightweight, and high-performance sandwich panels designed for a wide range of construction applications where thermal insulation and structural integrity are paramount. Comprising a rigid Polyurethane Foam (PUF) core sandwiched between two structural facing sheets, usually pre-painted galvanized iron (PPGI), pre-painted galvanized steel (PPGS), or aluminum, these panels offer superior thermal insulation and rapid construction benefits.

Ideal for both internal and external applications, Puf Panels are the go-to solution for creating energy-efficient, durable, and hygienic environments across various industries.

Key Features & Benefits:

- Exceptional Thermal Insulation: Featuring a low thermal conductivity (K-value) PUF core, our panels significantly reduce heat transfer, leading to substantial energy savings in heating and cooling. Maintain stable internal temperatures with minimal energy consumption.

- Lightweight & High Strength-to-Weight Ratio: Despite their high strength and rigidity, PUF panels are remarkably lightweight. This simplifies handling and installation, reduces labor costs, and lowers the overall structural load on buildings, potentially saving on foundation costs.

- Durability & Longevity: Built to withstand harsh environmental conditions, these panels are resistant to corrosion, moisture, and common building ailments. The robust construction ensures a long service life with minimal maintenance.

- Rapid & Easy Installation: Their modular design and pre-engineered nature allow for quick and efficient installation. Panels are manufactured to precise dimensions, accelerating project timelines and reducing on-site construction complexities and waste.

- Superior Energy Efficiency: By creating an effective thermal envelope, PUF panels drastically cut down energy consumption, contributing to lower operating costs, increased sustainability, and a reduced carbon footprint.

- Hygienic & Food-Safe: The non-porous and easy-to-clean surfaces make them ideal for sterile environments like clean rooms, pharmaceutical facilities, food processing units, and cold storage, preventing bacterial growth and ensuring hygiene.

- Fire Retardant Options: Available with fire-retardant additives in the PUF core, meeting various fire safety standards and providing an added layer of safety to your structures.

- Aesthetic Versatility: Available in various colors, finishes, and profiles for the facing sheets, allowing for design flexibility and an appealing architectural appearance that complements any project.

- Sound Insulation: The dense PUF core also provides good acoustic properties, contributing to quieter indoor environments.

Technical Specifications:

- Core Material: High-Density Closed-Cell Polyurethane Foam (PUF)

- Core Density: 38-42 kg/m³ (can be customized)

- Panel Thickness: 30 mm to 200 mm (available in various increments, e.g., 50mm, 75mm, 100mm, 120mm, 150mm, 200mm)

- Facing Materials:

- Pre-Painted Galvanized Iron (PPGI) / Steel (PPGS)

- Aluminium (Plain, Stucco Embossed, or Pre-painted)

- Stainless Steel (SS 304 / SS 316)

- FRP (Fiber Reinforced Polymer)

- Custom options available

- Facing Sheet Thickness: 0.4 mm to 0.8 mm (or customized as per requirement)

- Thermal Conductivity (K-value): Approximately 0.021 W/mK (one of the lowest in insulation materials)

- Standard Panel Width: 950 mm / 1000 mm / 1150 mm (effective covering width)

- Panel Length: Up to 12 meters (customizable as per project specifications)

- Joint System:

- Tongue & Groove: For standard walling, roofing, and general insulation.

- Cam-lock: Specifically designed for cold rooms and freezer rooms to ensure a perfectly sealed and airtight joint.

- Fire Rating: Available in various classifications, including B2 (Self-Extinguishing) and B1 (Fire Retardant), depending on core formulation.

- Service Temperature Range: -40°C to +80°C (depending on facing material)

Ideal Applications:

Puf Panels are a versatile building solution, perfect for a multitude of applications including:

- Cold Storage & Freezer Rooms: Essential for maintaining precise temperature control in food, pharmaceutical, and chemical industries.

- Clean Rooms: Pharmaceutical manufacturing, electronics assembly, laboratories, and healthcare facilities requiring sterile, dust-free environments.

- Food Processing & Packaging Units: Ensuring hygiene, temperature stability, and compliance with food safety standards.

- Industrial Sheds & Warehouses: For thermal insulation of roofs, walls, and partitions, improving energy efficiency and comfort.

- Modular Buildings & Prefabricated Structures: Providing quick, efficient, and insulated construction for temporary or permanent facilities.

- Commercial & Retail Spaces: Creating energy-efficient building envelopes for showrooms, supermarkets, and offices.

- Insulated Roofing & Wall Cladding: For any building requiring high thermal performance and a modern aesthetic.

- Telecom Shelters & Data Centers: Protecting sensitive equipment from temperature fluctuations.

- Agricultural Buildings: Insulating poultry farms, dairy farms, and greenhouses.

Why Choose Our Puf Panels?

We are committed to delivering excellence in every panel. Our Puf Panels are manufactured using state-of-the-art technology, premium-grade raw materials, and stringent quality control processes, ensuring consistent quality, superior performance, and strict adherence to industry standards.

- Customization: We offer tailored panel dimensions, facing materials, and finishes to meet your specific project requirements.

- Quality Assurance: Rigorous testing at every stage of manufacturing guarantees the durability, thermal performance, and longevity of our panels.

- Expert Support: Our experienced team provides comprehensive technical assistance, from product selection and design consultation to installation guidance.

- Sustainable Solutions: By contributing to energy-efficient buildings, our Puf Panels help reduce operational costs and support a greener, more sustainable future.

Elevate your construction project with the unmatched performance, efficiency, and durability of our Puf Panels. Contact us today for a consultation, detailed specifications, or to request a quote!