Description

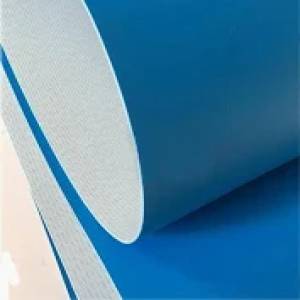

High-Performance PU Conveyor Belts: Durability, Flexibility, and Efficiency

Our range of polyurethane (PU) conveyor belts offers superior performance and longevity for a wide array of industries. Manufactured using high-quality polyurethane compounds, these belts combine exceptional durability with impressive flexibility, providing a cost-effective and reliable solution for diverse material handling applications.

Key Features & Benefits:

- Exceptional Abrasion Resistance: PU belts significantly outperform traditional rubber belts in abrasion-resistant applications, leading to extended service life and reduced replacement costs. This makes them ideal for handling abrasive materials like gravel, sand, and minerals.

- High Tensile Strength: Our PU belts boast exceptional tensile strength, ensuring reliable performance even under heavy loads and demanding operating conditions. This translates to increased throughput and reduced downtime.

- Superior Flexibility: Unlike stiffer rubber belts, PU belts offer excellent flexibility, allowing for smooth operation around tight curves and smaller pulleys. This adaptability enhances efficiency and reduces wear on the belt and drive components.

- Oil and Chemical Resistance: Many of our PU belts are formulated with enhanced resistance to oils, greases, and various chemicals, making them suitable for applications involving oily or chemically aggressive materials. Specific chemical resistance varies depending on the chosen PU compound – please consult our detailed specifications.

- Wide Temperature Range: PU belts generally operate effectively across a broader temperature range compared to rubber alternatives, enhancing their versatility in different environments. Specific temperature ranges are detailed in the technical specifications for each belt type.

- Hygiene and Cleanability: PU belts are relatively easy to clean and maintain, making them a suitable choice for food processing, pharmaceutical, and other hygiene-sensitive industries. Certain formulations meet FDA compliance requirements.

- Customizable Options: We offer a range of customizable options to meet your specific needs, including different belt thicknesses, widths, lengths, and surface finishes. We can also incorporate features such as cleats, sidewalls, and other specialized constructions.

Applications:

Our PU conveyor belts are ideal for a wide range of applications, including:

- Mining and Aggregates: Handling abrasive materials like rock, gravel, and sand.

- Food Processing: Transporting food products in hygienic conditions.

- Packaging and Logistics: Moving boxes, parcels, and other packaged goods.

- Manufacturing: Conveying parts and materials within industrial processes.

- Pharmaceutical: Handling sensitive materials in controlled environments.

- Recycling: Processing waste materials.

Specifications:

Detailed specifications, including available thicknesses, widths, tensile strengths, temperature ranges, and chemical resistance data, are available upon request. Please contact us with your specific requirements to determine the optimal PU conveyor belt for your application. We can provide detailed technical data sheets and samples to aid in your selection process.

Ordering Information:

To order, please provide the following information:

- Required belt width

- Required belt length

- Desired thickness

- Specific material handling requirements

- Any desired special features (e.g., cleats, sidewalls)

Contact us today to discuss your conveyor belt needs and receive a customized quote. We are committed to providing high-quality products and exceptional customer service.