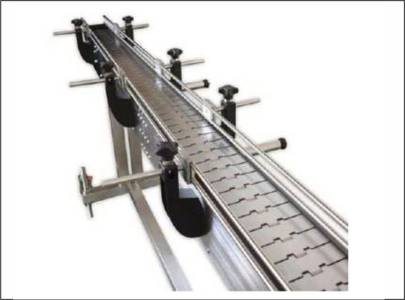

Slat conveyors are robust and reliable material handling systems ideal for transporting a wide range of products in various industries. These conveyors utilize interconnected slats, mounted on chains or belts, to move items along a defined path. Unlike belt conveyors, slat conveyors offer superior control and handling capabilities, making them suitable for delicate or irregularly shaped goods.

Key Features & Benefits:

Applications:

Slat conveyors are utilized across a broad spectrum of industries, including:

Specifications (Example - Varies by Model):

Choosing the Right Slat Conveyor:

Selecting the appropriate slat conveyor depends on factors such as the product being conveyed, the required capacity, the available space, and budget constraints. Consulting with a material handling specialist is recommended to ensure you choose the optimal system for your specific needs. We offer personalized consultations and can assist you in designing a custom solution to maximize efficiency and productivity. Contact us today for a quote and to discuss your requirements.