Description

Screw Conveyors: Efficient and Reliable Material Handling Solutions

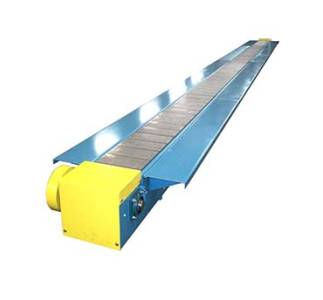

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly versatile and efficient machines designed for the conveying of a wide range of materials. They excel in applications requiring gentle yet effective transport, offering a cost-effective and reliable solution for various industries.

How They Work:

Screw conveyors utilize a rotating helical screw blade, or auger, housed within a trough. As the screw rotates, it pushes the material along the trough, moving it from one point to another. The gentle action minimizes material degradation, making them ideal for fragile or sensitive products. The enclosed design also prevents material spillage and contamination.

Key Features & Benefits:

- Versatile Material Handling: Screw conveyors can handle a wide variety of materials, including powders, granules, flakes, chips, and small solids. They can also handle materials with varying moisture content, although specific design considerations may be needed for extremely wet or sticky substances.

- Gentle Material Handling: The rotational movement minimizes product damage, making them suitable for fragile materials like pharmaceuticals, food products, and plastics.

- Reliable and Efficient: Screw conveyors provide consistent and reliable conveying, with minimal maintenance required. They offer high throughput capacity depending on the screw design and motor power.

- Compact Design: Screw conveyors often require less space compared to other conveying systems, making them ideal for applications with limited floor space.

- Customizable Design: Screw conveyors are highly customizable to meet specific application needs. Customization options include:

- Trough Material: Various materials are available, including mild steel, stainless steel (for food, pharmaceutical, and corrosive materials), and other specialized alloys.

- Screw Design: Different screw flight designs (e.g., single, double, ribbon) are available to optimize for different material properties and conveying needs.

- Length and Diameter: Conveyors can be designed to specific lengths and diameters to fit your facility's layout and throughput requirements.

- Drive System: Various drive options are available, including gear motors, variable frequency drives (VFDs) for speed control, and different power ratings to match the application.

- Inlet and Outlet Configurations: Customizable inlets and outlets ensure seamless integration with existing equipment.

- Additional Features: Options like heating jackets for temperature control, safety features, and cleaning systems can be added.

Applications:

Screw conveyors find widespread use in numerous industries, including:

- Food Processing: Conveying grains, powders, and other ingredients.

- Pharmaceutical Manufacturing: Handling sensitive powders and tablets.

- Chemical Processing: Transporting powders and granules.

- Plastics Processing: Moving plastic pellets and flakes.

- Waste Management: Conveying waste materials.

- Agricultural: Moving grains and feed.

Choosing the Right Screw Conveyor:

Selecting the appropriate screw conveyor requires careful consideration of several factors:

- Material properties: Bulk density, particle size, abrasiveness, and moisture content.

- Throughput requirements: The desired conveying capacity.

- Conveying distance: The length of the conveyor.

- Environmental conditions: Temperature, humidity, and potential for corrosion.

- Space constraints: The available space for installation.

Contact us today to discuss your specific material handling needs and let our experts help you choose the optimal screw conveyor for your application.