Description

Screw Conveyors: Efficient Material Handling Solutions

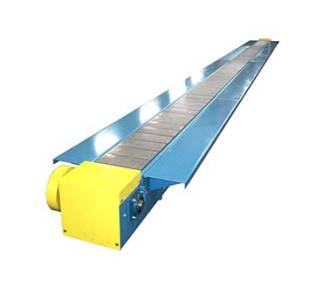

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly versatile and efficient machines designed for the bulk handling of a wide range of materials. They offer a reliable and cost-effective solution for moving materials horizontally, inclined, or even vertically, making them ideal for various industries.

How They Work:

A screw conveyor consists of a helical screw blade rotating within a trough. The rotating screw pushes the material along the trough, conveying it from the inlet to the outlet. The design allows for gentle material handling, minimizing damage and degradation, making them suitable for fragile products.

Key Features and Benefits:

- Versatility: Handle a wide variety of materials, including powders, granules, flakes, chips, and small solids. Can accommodate both dry and semi-moist materials.

- Efficiency: Provides consistent and controlled material flow, optimizing production processes.

- Gentle Handling: Reduces material degradation and breakage compared to other methods.

- Compact Design: Requires less space compared to other bulk handling systems.

- Customizable: Available in various sizes, materials, and configurations to meet specific application needs. Options include different trough materials (steel, stainless steel, polymer), screw designs (single flight, double flight), and drive systems.

- Easy Maintenance: Modular design allows for easy access to components for cleaning and repair.

- Cost-Effective: Offers a lower total cost of ownership compared to other bulk handling solutions due to lower energy consumption and reduced maintenance.

- Precise Control: Enables accurate metering and dispensing of materials.

Applications:

Screw conveyors find extensive use in a variety of industries, including:

- Food Processing: Conveying ingredients, powders, and finished products.

- Pharmaceutical: Handling powders, granules, and tablets.

- Chemical: Conveying powders, granules, and pastes.

- Agricultural: Moving grains, seeds, and feedstuffs.

- Waste Management: Handling various types of waste materials.

- Mining: Conveying ores and other materials.

- Manufacturing: Moving components and materials within the production line.

Specifications (Varied depending on model):

- Trough Material: Carbon steel, stainless steel, aluminum, polymer (specify material and grade)

- Screw Diameter: Available in a range of diameters to match material volume requirements.

- Screw Length: Customizable to fit specific application needs.

- Capacity: Varies significantly based on material properties, screw diameter, and rotational speed. (Specific capacity to be provided on request)

- Drive System: Electric motor, hydraulic motor (Specify available options)

- Power Requirements: Dependent on the size and capacity of the conveyor. (Specific power requirements to be provided on request)

Optional Features:

- Discharge gates: For precise material control.

- Variable speed drives: For optimal control of material flow.

- Heating or cooling jackets: For temperature sensitive materials.

- Safety features: Emergency stops, interlocks, and safety guards.

Contact us today to discuss your specific material handling needs and receive a customized quote. We offer a wide range of screw conveyor options to meet your exact requirements. Let our experts help you find the perfect solution for your application.