Description

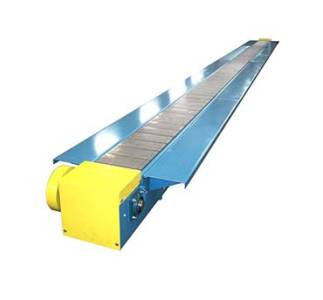

Screw Conveyors: Efficient Material Handling Solutions

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly versatile and efficient machines used for the conveying of a wide range of bulk materials. They excel in applications requiring gentle, controlled movement of products, minimizing damage and degradation. Whether you need to transport powders, granules, flakes, or even small pieces of solid materials, a screw conveyor offers a robust and reliable solution.

How They Work:

A screw conveyor operates using a helical screw blade rotating within a trough-shaped housing. The rotating screw pushes the material along the trough, effectively conveying it from one point to another. The design allows for precise control over the material flow rate, making it ideal for various industrial processes.

Key Features and Benefits:

- Versatile Material Handling: Handle a broad spectrum of materials, including powders, granules, chips, flakes, and small solids. Specific applications and material properties will determine the appropriate screw conveyor design.

- Gentle Material Handling: Minimizes material damage and degradation, ideal for fragile or easily-crushed materials.

- Precise Control: Easily adjust the conveying speed and flow rate for precise control over material movement.

- Compact Design: Space-saving design, making them suitable for applications with limited space.

- High Efficiency: Reliable and efficient operation, minimizing downtime and energy consumption.

- Durable Construction: Typically constructed from robust materials like stainless steel, carbon steel, or other corrosion-resistant materials, depending on the application and material handled.

- Customization Options: Available in various sizes, lengths, and configurations to meet specific application requirements. Options include different screw flight designs, trough materials, and drive systems.

- Easy Maintenance: Designed for easy access to components for routine maintenance and cleaning.

- Various Discharge Options: Multiple discharge options are available, including end discharge, intermediate discharge, and side discharge, to suit your process needs.

Applications:

Screw conveyors find widespread applications across diverse industries, including:

- Food Processing: Conveying ingredients, finished products, and byproducts.

- Chemical Processing: Handling powders, granules, and other chemical materials.

- Pharmaceutical Industry: Gentle and controlled movement of sensitive pharmaceutical ingredients.

- Agricultural Industry: Conveying grains, seeds, and other agricultural products.

- Waste Management: Handling solid waste materials.

- Mining and Quarrying: Transporting minerals and other materials.

Specifications (Typical, Customizable):

- Trough Material: Stainless steel, carbon steel, galvanized steel, etc.

- Screw Flight Material: Stainless steel, carbon steel, etc.

- Drive System: Electric motor, hydraulic motor, etc.

- Capacity: Variable, dependent on design and material properties.

- Length: Customizable to fit your specific requirements.

- Diameter: Variable, dependent on capacity and material properties.

Contact us today to discuss your specific material handling needs and determine the optimal screw conveyor solution for your application. We offer custom design and engineering services to ensure the perfect fit for your unique requirements.