Description

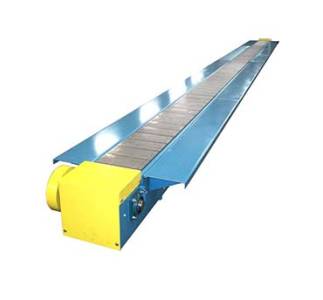

Screw Conveyors: Efficient & Reliable Material Handling Solutions

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly efficient and versatile machines designed for the gentle and controlled movement of a wide range of bulk materials. Whether you need to move powders, granules, flakes, or small pieces of solids, screw conveyors offer a reliable and cost-effective solution for various industries.

How They Work:

A screw conveyor consists of a helical screw blade rotating within a trough-like casing. The rotating screw flights propel the material along the trough, facilitating its movement from an inlet point to an outlet point. This gentle, non-damaging action makes them ideal for fragile materials. The direction of material flow is determined by the direction of the screw's rotation.

Key Features & Benefits:

- Gentle Material Handling: Minimizes material degradation and damage, making them suitable for sensitive products.

- Versatile Applications: Handles a wide array of materials with varying properties, from fine powders to larger, coarser materials.

- Precise Control: Allows for accurate control of material flow rate through speed adjustment.

- Compact Design: Often requires less space compared to other conveying systems, making them suitable for smaller facilities.

- Cost-Effective: Relatively low initial investment and operating costs compared to alternative conveying methods.

- Sealed Design Options: Available with sealed troughs to prevent material spillage and maintain a clean environment.

- Customizable: Can be customized to meet specific application requirements, including length, trough diameter, material of construction, and drive system.

- Durable Construction: Built from high-quality materials to withstand harsh operating conditions and ensure long-lasting performance.

- Low Maintenance: Require minimal maintenance with regular lubrication and inspection.

Applications:

Screw conveyors find widespread use in numerous industries, including:

- Food Processing: Moving ingredients, grains, and processed foods.

- Chemical Processing: Handling powders, granules, and other chemical materials.

- Pharmaceutical Industry: Conveying powders and granules in a controlled and sanitary environment.

- Waste Management: Transporting waste materials for processing and disposal.

- Agricultural: Moving grains, seeds, and other agricultural products.

- Mining and Minerals Processing: Transporting various minerals and materials.

Specifications & Options:

Our screw conveyors are available in a wide range of specifications to meet your unique needs:

- Material of Construction: Stainless steel, carbon steel, and other specialized materials are available to ensure compatibility with your specific material and environment.

- Trough Size and Length: Customized to match your required capacity and throughput.

- Drive Systems: Various drive options are available, including electric motors, gear reducers, and variable frequency drives (VFDs) for precise speed control.

- Discharge Options: Multiple discharge options are available, including end discharge, side discharge, and multiple discharge points.

- Safety Features: Equipped with various safety features to ensure safe operation.

Contact Us:

Ready to improve your material handling efficiency? Contact us today to discuss your specific needs and receive a customized quote for a screw conveyor tailored to your application. We offer expert consultation and engineering support to help you select the ideal system for your requirements.