Description

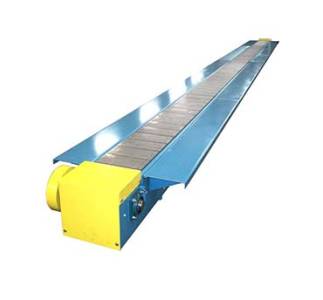

Screw Conveyors: Efficient & Reliable Material Handling Solutions

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly efficient and versatile machines used for the conveying of a wide range of bulk materials. They offer a reliable and cost-effective solution for transporting materials horizontally, inclined, or even vertically, making them ideal for various industries.

How They Work:

A screw conveyor consists of a helical screw blade, or flighting, rotating within a trough. The rotating screw pushes the material along the trough, effectively moving it from the inlet to the outlet. This simple yet effective design allows for gentle and controlled material handling, minimizing damage and degradation.

Key Features & Benefits:

- Versatile Material Handling: Suitable for handling a wide variety of materials, including powders, granules, flakes, pellets, and even some light, free-flowing solids. Specific flighting designs can be tailored to accommodate sticky or abrasive materials.

- Gentle Material Handling: Reduces material breakage and degradation, protecting product quality, especially important for sensitive or fragile materials.

- Precise Control: Allows for precise control over material flow rate and discharge point. Variable speed drives can further enhance control and efficiency.

- Compact Design: Space-saving design, ideal for applications with limited space.

- Cost-Effective: Lower initial investment and operational costs compared to other material handling systems.

- Easy Maintenance: Modular design simplifies maintenance and repair, minimizing downtime.

- Durable Construction: Built from high-quality materials, ensuring long-lasting performance even in demanding applications. Materials like stainless steel offer superior corrosion resistance for specific environments.

- Customization Options: Available in various sizes, lengths, and materials to meet specific application requirements. Custom flighting designs and options for heating/cooling can be incorporated.

Applications:

Screw conveyors find applications across a broad range of industries, including:

- Food Processing: Transporting ingredients, powders, and finished products.

- Agriculture: Moving grains, seeds, and feedstuffs.

- Chemical Processing: Conveying powders, granules, and pellets.

- Pharmaceutical: Handling delicate powders and pharmaceutical ingredients.

- Mining & Aggregates: Transporting ores, minerals, and other bulk materials.

- Waste Management: Moving waste materials for processing and disposal.

- Wood Processing: Handling wood chips and sawdust.

Types of Screw Conveyors:

Different designs cater to various needs:

- Horizontal Screw Conveyors: For conveying materials horizontally.

- Inclined Screw Conveyors: For conveying materials at an angle.

- Vertical Screw Conveyors: For lifting materials vertically.

- U-Trough Screw Conveyors: For efficient conveying and discharge.

Choosing the Right Screw Conveyor:

Selecting the appropriate screw conveyor involves considering factors like:

- Material properties: Density, flowability, abrasiveness, temperature, and moisture content.

- Capacity requirements: The volume of material to be conveyed per unit of time.

- Conveyance distance and inclination: The length and angle of the conveyor.

- Environmental conditions: Temperature, humidity, and potential for corrosion.

- Space constraints: Available space for installation and operation.

Contact us today to discuss your specific material handling needs and let our experts help you select the optimal screw conveyor solution for your application.