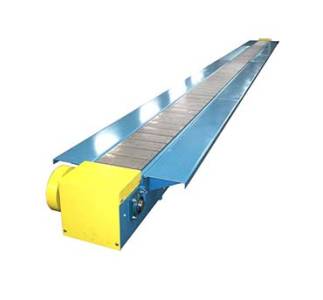

Screw conveyors, also known as auger conveyors or spiral conveyors, provide a highly efficient and versatile method for transporting a wide range of bulk materials. Whether you need to move powders, granules, chips, or even light solids, our screw conveyors offer a reliable and cost-effective solution for your material handling needs.

Key Features & Benefits:

Applications:

Screw conveyors are widely used across diverse industries, including:

Specifications (Example - Customizable):

Options & Accessories:

Contact us today to discuss your specific material handling needs and receive a customized quote for a screw conveyor solution tailored to your application. Our experienced engineers will work with you to determine the optimal configuration to maximize efficiency and meet your exact requirements.