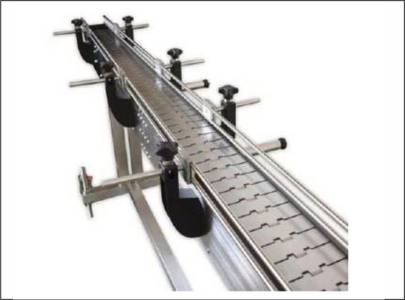

Slat conveyors offer a robust and reliable solution for transporting a wide range of products across various industries. Their unique design, utilizing interconnected slats mounted on a chain system, provides a gentle yet efficient method of conveying materials, even those that are fragile or irregularly shaped. Unlike belt conveyors, slat conveyors excel in handling items that require controlled spacing, preventing damage from bunching or overlapping.

Key Features and Benefits:

Applications:

Slat conveyors find application in a wide array of industries, including:

Choosing the Right Slat Conveyor:

Selecting the appropriate slat conveyor involves considering factors such as:

Contact us today to discuss your specific material handling needs and let us help you design a custom slat conveyor solution that maximizes efficiency and minimizes costs.