Description

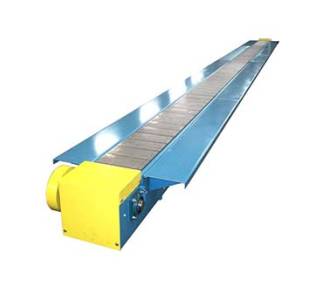

Screw Conveyors: Efficient & Reliable Material Handling Solutions

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly efficient and versatile machines used for the gentle and controlled movement of a wide range of bulk materials. They offer a reliable and cost-effective solution for numerous industries, providing precise material handling with minimal product degradation.

How They Work:

A screw conveyor consists of a helical screw blade rotating within a trough or tube. The rotating screw pushes the material along the trough, enabling horizontal, inclined, or even vertical conveying. The design allows for gentle handling, minimizing damage to fragile materials. The speed of the screw and the trough's inclination determine the conveying capacity and speed.

Key Features & Benefits:

- Versatile Material Handling: Screw conveyors can handle a wide variety of materials, including powders, granules, flakes, chips, and small solids. They are suitable for both dry and slightly moist materials, depending on the specific design and material compatibility.

- Gentle Material Handling: The gentle, controlled movement minimizes material degradation and breakage, making them ideal for sensitive products.

- Efficient and Reliable Operation: Screw conveyors boast high efficiency and reliability, offering consistent performance with minimal maintenance.

- Precise Material Control: The design allows for accurate control over material flow rate and discharge point.

- Compact Footprint: Compared to other conveying systems, screw conveyors often have a smaller footprint, saving valuable space in your facility.

- Customizable Design: Screw conveyors can be custom-designed to meet specific application requirements, including trough length, diameter, material, and capacity. Options include different screw flights, materials of construction (stainless steel, carbon steel, etc.), and various discharge mechanisms.

- Cost-Effective: While the initial investment may vary, screw conveyors often prove to be cost-effective in the long run due to their low maintenance requirements and efficient operation.

- Easy Integration: They can be easily integrated into existing production lines and systems.

- Low Maintenance: With proper lubrication and routine inspection, screw conveyors require minimal maintenance.

Applications:

Screw conveyors find applications across diverse industries, including:

- Food Processing: Conveying ingredients, powders, and finished products.

- Pharmaceutical: Handling delicate powders and granules.

- Chemical Processing: Moving dry chemicals and powders.

- Agricultural: Conveying grains, seeds, and feed.

- Waste Management: Handling various types of waste materials.

- Mining & Quarrying: Transporting small sized ore and minerals.

Types of Screw Conveyors:

Various screw conveyor types cater to specific needs, including:

- Horizontal Screw Conveyors: For horizontal material transport.

- Inclined Screw Conveyors: For conveying materials at an angle.

- Vertical Screw Conveyors: For lifting materials vertically.

- U-Trough Screw Conveyors: Employing a U-shaped trough for enhanced material flow.

Choosing the Right Screw Conveyor:

Selecting the appropriate screw conveyor involves careful consideration of several factors, including:

- Material properties: Density, particle size, abrasiveness, and moisture content.

- Capacity requirements: The volume of material to be conveyed per unit of time.

- Conveying distance and inclination: The length and angle of the conveyor.

- Environmental conditions: Temperature, humidity, and potential exposure to corrosive substances.

Contact us today to discuss your specific material handling needs and let us help you find the perfect screw conveyor solution for your application.