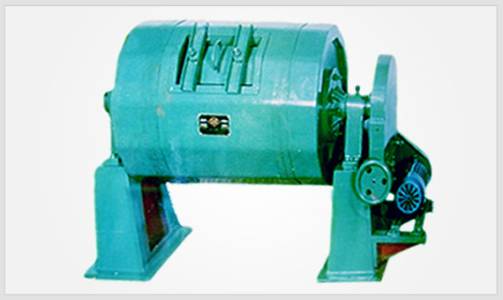

Tired of slow, inefficient, and inconsistent manual tinning? Upgrade your operation with our cutting-edge Automated Tinning Drum Machine, designed to dramatically improve your productivity, consistency, and overall quality. This robust machine offers unparalleled precision and speed, making it the ideal solution for high-volume tinning applications across various industries.

Key Features & Benefits:

Technical Specifications:

Included Accessories:

Optional Accessories:

Investment & ROI:

The initial investment in our automated tinning drum machine quickly translates into significant returns through increased productivity, reduced labor costs, improved quality, and minimized waste. Contact us for a detailed ROI analysis based on your specific production needs.

Contact Us Today:

Ready to revolutionize your tinning process? Contact our sales team to learn more about our Automated Tinning Drum Machine and request a customized quote. We're committed to providing you with the best tinning solution for your business.