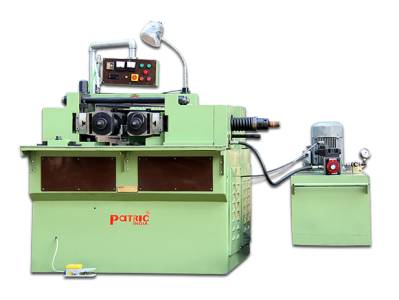

Revolutionize your threading operations with our robust and efficient Hydraulic Thread Rolling Machine. Designed for superior performance and longevity, this machine offers a cost-effective and environmentally friendly alternative to traditional cutting methods. Perfect for high-volume production environments, it delivers precise, high-quality threads with minimal material waste.

Key Features & Benefits:

Technical Specifications:

Applications:

This Hydraulic Thread Rolling Machine finds extensive applications in various industries, including:

Contact us today to learn more about our Hydraulic Thread Rolling Machine and how it can enhance your production process. Request a quote or schedule a demonstration.