Description

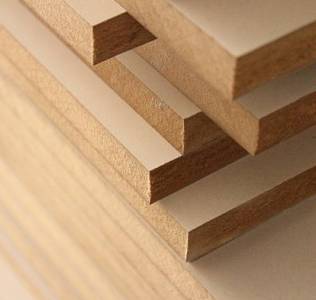

Medium & High-Density Fiberboard (MDF & HDF): Your Versatile Wood Alternative

Introducing our range of high-quality Medium-Density Fiberboard (MDF) and High-Density Fiberboard (HDF), offering exceptional performance and versatility for a wide array of applications.

These engineered wood products are created by breaking down hardwood or softwood fibers, combining them with resin, and then pressing them under high temperature and pressure to form dense, uniform panels. This process results in a material that's both strong and consistent, exceeding the capabilities of many natural wood types.

Medium-Density Fiberboard (MDF):

- Density: Typically ranges from 500 to 800 kg/m³.

- Characteristics: Offers a smooth, fine surface ideal for painting, laminating, and veneering. It's relatively easy to machine and offers good dimensional stability. Less dense than HDF, making it lighter and easier to handle.

- Applications: Perfect for furniture manufacturing (cabinets, shelving, drawers), interior trim, decorative molding, craft projects, and various construction applications where a smooth, paintable surface is desired.

High-Density Fiberboard (HDF):

- Density: Typically ranges from 800 kg/m³ and above.

- Characteristics: Significantly denser and stronger than MDF, offering superior impact resistance and durability. Excellent for applications requiring high strength and stability. Can be more challenging to machine than MDF.

- Applications: Ideal for flooring underlayment, heavy-duty shelving, high-impact furniture components (tabletops, work surfaces), industrial applications, and wherever exceptional strength and resilience are critical.

Key Benefits of Both MDF & HDF:

- Uniformity: Consistent density and texture throughout the panel, ensuring reliable performance.

- Smooth Surface: Provides an excellent base for finishing, minimizing the need for extensive sanding.

- Dimensional Stability: Resists warping and shrinking, maintaining its shape even in fluctuating humidity conditions.

- Cost-Effective: A more affordable alternative to solid wood, offering excellent value for money.

- Versatile: Suitable for a wide range of applications, from delicate crafts to robust industrial projects.

- Easy to Machine: Can be easily cut, shaped, and drilled using standard woodworking tools (ease of machining varies slightly between MDF and HDF).

Available Sizes & Thicknesses:

We offer a variety of sizes and thicknesses for both MDF and HDF to suit your specific needs. Please contact us for detailed information on available options. Custom sizes may be available upon request.

Specifications:

- Formaldehyde Emission: Complies with all relevant environmental standards. (Specific certifications available upon request).

- Moisture Content: Carefully controlled to ensure optimal performance.

Choosing Between MDF and HDF:

Selecting between MDF and HDF depends on your project's requirements. If you need a smooth, paintable surface for less demanding applications, MDF is a great choice. For applications requiring superior strength and durability, HDF is the preferred option.

Order yours today and experience the quality and versatility of our MDF and HDF fiberboards!