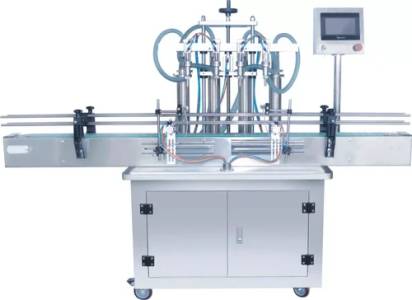

This robust and versatile stainless steel liquid filling machine is engineered for precise and efficient filling of various liquids across diverse industries. Built with durability and hygiene in mind, this machine is ideal for food, beverage, pharmaceutical, and chemical applications.

Key Features:

Technical Specifications:

Benefits:

Warranty:

(Specify warranty period and details).

Contact us today for a quote and to discuss your specific liquid filling requirements!

(Include contact information here)