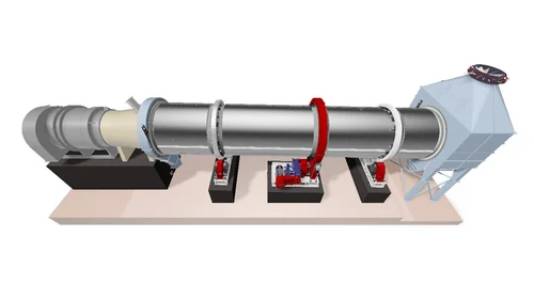

Our Calcination Rotary Kiln is a highly efficient and reliable industrial equipment designed for the thermal processing of various materials. Ideal for applications requiring precise temperature control and consistent product quality, this kiln excels in calcination processes, transforming raw materials into valuable products through controlled heating.

Key Features & Benefits:

Specifications: (Specific specifications will be provided upon request based on your individual needs. This includes dimensions, capacity, throughput, power requirements, and other relevant data.)

Contact us today to discuss your specific requirements and receive a customized quotation for your Calcination Rotary Kiln. Our experienced engineers will assist you in selecting the optimal configuration to meet your production needs and budget.