Description

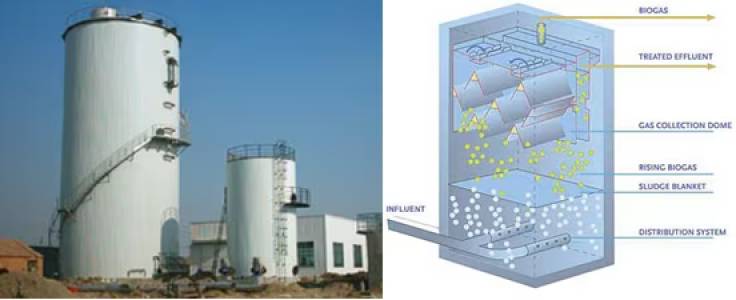

UASBR: Upflow Anaerobic Sludge Blanket Reactor - A High-Efficiency Wastewater Treatment Solution

The UASBR (Upflow Anaerobic Sludge Blanket Reactor) represents a cutting-edge advancement in anaerobic wastewater treatment. This innovative technology offers a compact, highly efficient, and cost-effective solution for treating a wide range of organic wastewaters, surpassing traditional anaerobic digesters in performance and versatility.

Key Features and Benefits:

- High Treatment Efficiency: UASBRs achieve significantly higher organic matter removal rates compared to conventional anaerobic systems. This is due to the high concentration of biomass within the sludge blanket, resulting in enhanced substrate-microbe contact and accelerated biodegradation. Expect superior COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) reduction.

- Compact Design: The upflow configuration allows for a significantly smaller footprint compared to traditional anaerobic digesters, making it ideal for space-constrained applications. This reduces both capital and land costs.

- Robust Performance: The system is designed for high organic loading rates (OLR) and variable influent flow rates, making it highly resilient and adaptable to fluctuating operational conditions. It exhibits excellent stability even with fluctuations in wastewater characteristics.

- Reduced Sludge Production: UASBRs generate less sludge than other anaerobic treatment methods, minimizing sludge handling and disposal costs.

- Low Energy Consumption: The inherent mixing mechanism within the reactor reduces the need for external energy input for mixing, resulting in lower operational costs.

- Versatile Applications: UASBR technology is suitable for a wide range of applications, including:

- Municipal wastewater treatment

- Industrial wastewater treatment (e.g., food processing, breweries, dairies)

- Agricultural wastewater treatment

- Landfill leachate treatment

- Palm oil mill effluent (POME) treatment

Operational Principles:

Wastewater enters the bottom of the reactor and flows upwards through a dense sludge blanket composed of anaerobic microorganisms. These microorganisms, predominantly methanogens and acidogens, consume organic matter, producing biogas (primarily methane and carbon dioxide) as a byproduct. The biogas is collected at the top of the reactor. The treated effluent overflows from the top. The sludge blanket is maintained through a delicate balance between the upward flow of wastewater and the settling of biomass.

Technical Specifications (Variable based on specific design):

- Reactor Dimensions: Customizable depending on treatment capacity requirements.

- Retention Time: Typically ranges from several hours to a day, depending on the wastewater characteristics and desired treatment level.

- Hydraulic Loading Rate (HLR): Dependent on the design and influent characteristics.

- Organic Loading Rate (OLR): Dependent on the design and influent characteristics.

- Materials of Construction: Typically corrosion-resistant materials such as stainless steel, fiberglass reinforced plastic (FRP), or concrete are used.

Advantages over other Anaerobic Systems:

Compared to other anaerobic treatment systems like anaerobic contact processes or anaerobic filters, UASBRs offer superior treatment efficiency, a smaller footprint, and lower energy requirements.

Conclusion:

The UASBR offers a superior and sustainable solution for anaerobic wastewater treatment. Its high efficiency, compact design, and robust performance make it a cost-effective and environmentally friendly choice for a wide range of applications. Contact us today to discuss your specific wastewater treatment needs and explore the potential benefits of a UASBR system.