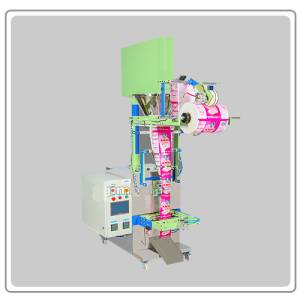

Revolutionize your powder packaging with the AP-1000, a high-speed, fully automatic machine designed for efficient and precise packaging of various powdered products. This robust machine is perfect for food, pharmaceutical, chemical, and cosmetic industries, offering unparalleled flexibility and output.

Contact us today for a personalized consultation and quote. Let the AP-1000 transform your powder packaging process!