Description

Ultra-High Molecular Weight Polyethylene (UHMWPE): The Ultimate in Wear Resistance

Ultra-High Molecular Weight Polyethylene (UHMWPE), also known as UHMW or polythene, is a remarkable thermoplastic polymer renowned for its exceptional properties. Its incredibly long molecular chains result in a material with superior wear resistance, impact strength, and chemical inertness, making it ideal for a vast range of demanding applications.

Unmatched Performance Characteristics:

- Exceptional Wear Resistance: UHMWPE boasts the lowest coefficient of friction of any thermoplastic, dramatically reducing wear and tear in applications involving sliding or abrasion. This translates to longer lifespan and reduced maintenance costs.

- High Impact Strength: Its toughness surpasses many metals and other plastics. UHMWPE can absorb significant impact energy without fracturing, making it ideal for applications requiring shock absorption and protection.

- Self-Lubricating: The low coefficient of friction minimizes the need for external lubrication, simplifying maintenance and reducing operating costs. This inherent self-lubricating property also contributes to its excellent wear resistance.

- Chemical Inertness: UHMWPE is resistant to a wide range of chemicals, including acids, alkalis, and many solvents. This inertness makes it suitable for use in harsh chemical environments.

- Low Water Absorption: Its minimal water absorption prevents swelling and maintains dimensional stability even in wet conditions.

- Non-Toxic: UHMWPE is considered biocompatible and non-toxic, making it suitable for food contact and medical applications.

- Lightweight: Despite its exceptional strength, UHMWPE is relatively lightweight, facilitating easier handling and installation.

Available Forms and Applications:

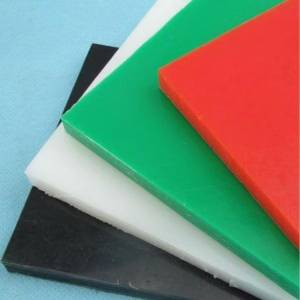

UHMWPE is available in various forms to suit different needs, including:

- Sheets & Plates: Ideal for lining, wear strips, cutting boards, and machine parts.

- Rods & Tubes: Used in conveyor systems, bushings, and bearings.

- Custom Machined Parts: Allows for precise fabrication to meet specific application requirements.

- Powders: Used in various molding and additive manufacturing processes.

Typical Applications:

The exceptional properties of UHMWPE make it suitable for a diverse range of applications, such as:

- Material Handling: Conveyor systems, chutes, and wear strips.

- Machinery: Bearings, gears, bushings, and slides.

- Food Processing: Cutting boards, conveyor belts, and processing equipment.

- Chemical Processing: Linings for tanks and pipes.

- Medical Devices: Implants, prosthetics, and surgical instruments.

- Automotive: Bumpers, wear pads, and other components.

Choosing the Right UHMWPE:

The specific grade of UHMWPE should be selected based on the application's requirements. Factors to consider include desired wear resistance, impact strength, and chemical compatibility. Our experts can assist in selecting the optimal grade for your specific needs.

Contact us today to learn more about UHMWPE and how it can improve the performance and longevity of your applications.