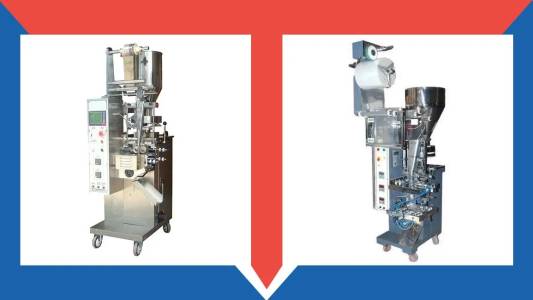

This robust and efficient Form-Fill-Seal (FFS) machine is designed for the automated packaging of granular and powdered products. Ideal for a wide range of industries, from food and pharmaceuticals to chemicals and cosmetics, this machine delivers high-speed production with exceptional accuracy and consistent package quality.

Key Features:

Technical Specifications: (Include a detailed table with specifications such as dimensions, power requirements, weight, production capacity, etc. Use a markdown table format for clarity).

| Specification | Value |

|---|---|

| Machine Dimensions | (Insert dimensions here) |

| Power Requirements | (Insert power requirements) |

| Weight | (Insert weight here) |

| Production Capacity | (Insert production capacity) |

| Filling Accuracy | (Insert filling accuracy) |

| Bag/Pouch Sizes | (Insert bag/pouch sizes) |

| Material Compatibility | (Insert compatible materials) |

Benefits:

Contact us today to learn more about our Form-Fill-Seal machine and find the perfect solution for your packaging needs.